When Grapes Ripen: Case Studies of Hyperspectral Field Detection

在葡萄種植與葡萄酒釀造領(lǐng)域,,準(zhǔn)確監(jiān)測葡萄成熟度和糖度是決定采收時(shí)機(jī)和最終酒品質(zhì)量的關(guān)鍵。高光譜成像技術(shù)已被證明能夠有效檢測葡萄的成熟度,、糖度(°Brix)和花青素含量,作為高光譜成像技術(shù)的專業(yè)提供商,,我們期待看到這項(xiàng)技術(shù)在葡萄品質(zhì)監(jiān)測中的創(chuàng)新應(yīng)用,。

目前大多數(shù)研究都局限于實(shí)驗(yàn)室環(huán)境或?qū)晤w葡萄進(jìn)行檢測。今天,,我們將聚焦兩項(xiàng)突破性研究,,展示高光譜技術(shù)如何在田間現(xiàn)場實(shí)現(xiàn)葡萄品質(zhì)的非破壞性監(jiān)測。

In viticulture and winemaking, accurately monitoring grape maturity and sugar content is crucial for determining optimal harvest timing and final wine quality. Hyperspectral imaging technology has proven effective in detecting grape maturity, sugar content (°Brix), and anthocyanin levels.As a professional provider of hyperspectral imaging solutions, we are excited to see innovative applications of this technology in grape quality monitoring.

Currently, most research has been limited to laboratory settings or single-berry measurements. Today, we highlight two groundbreaking studies demonstrating how hyperspectral technology enables non-destructive quality monitoring directly in the field.

『從實(shí)驗(yàn)室走向田間 / From Lab to Vineyard 』

意大利團(tuán)隊(duì)開發(fā)了一種基于可見光-近紅外(400-1000nm)高光譜相機(jī)的非破壞性方法,,直接在葡萄園中進(jìn)行13填的連續(xù)監(jiān)測,。他們使用偏最小二乘回歸(PLS)預(yù)測可溶性固形物含量,獲得R2=0.77的預(yù)測精度(RMSECV=0.79°Brix),,并通過偏最小二乘判別分析(PLS-DA)將葡萄按成熟度(以20°Brix為界)分類,,準(zhǔn)確率達(dá)86-91%。

An Italian research team developed a non-destructive method using visible-to-near-infrared (400-1000nm) hyperspectral cameras for continuous 13-day monitoring in vineyards. Using partial least squares regression (PLS), they achieved soluble solids content (SSC) predictions with R2=0.77 (RMSECV=0.79°Brix). Through partial least squares discriminant analysis (PLS-DA), they classified grape maturity (using 20°Brix as the threshold) with 86-91% accuracy.

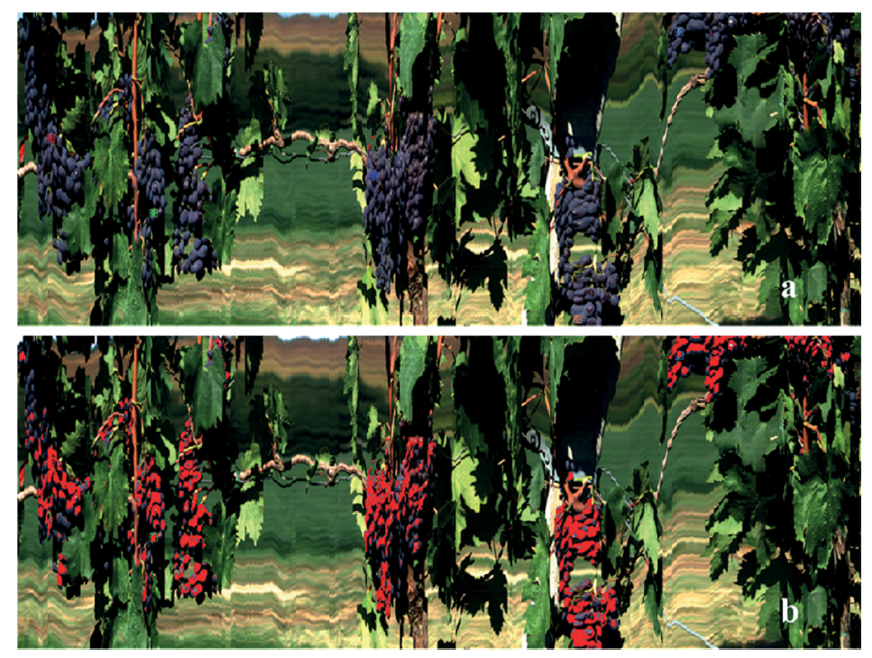

圖1 / Figure 1:

(a) RGB圖像來源于葡萄園行掃描截面的高光譜數(shù)據(jù),。 (b) 基于曼哈頓函數(shù)分類生成的ROI(紅色區(qū)域),。

(a) The RGB image is derived from hyperspectral data captured during a vineyard row scan transect.

(b) The region of interest (ROI, marked in red) was generated through classification using the Manhattan distance function.

『邊走邊測:硬件與算法的結(jié)合 / “On the Go” Monitoring: Hardware and Algorithm Synergy 』

西班牙團(tuán)隊(duì)的研究則更進(jìn)一步,他們開發(fā)了一套創(chuàng)新的"行進(jìn)間"高光譜成像系統(tǒng),,將可見光-近紅外高光譜相機(jī)(400-1000nm,、光譜分辨率2.1nm的)安裝在以5公里/小時(shí)速度移動的全地形車上。相機(jī)在車輛行進(jìn)過程中連續(xù)采集數(shù)據(jù),。

為適應(yīng)不同時(shí)段的光照變化,,系統(tǒng)會智能調(diào)整幀率(40-50幀/秒),每個測量區(qū)塊平均獲取710條掃描線,,總計(jì)約63.9萬個光譜像素點(diǎn),,。系統(tǒng)還配備RTK校正功能,,為所有采集數(shù)據(jù)提供厘米級的地理參考,。

A Spanish team advanced the technology further by developing an innovative "on-the-go" hyperspectral imaging system. They mounted a visible-to-near-infrared hyperspectral camera (400-1000nm, 2.1nm spectral resolution) on an all-terrain vehicle moving at 5 km/h, enabling continuous data acquisition during operation.

To adapt to varying light conditions, the system automatically adjusts frame rates (40-50 fps). Each measurement block captures approximately 710 scan lines, totaling ~639,000 spectral pixels. The system also integrates RTK correction for centimeter-level georeferencing of collected data.

圖2 / Figure 2:

使用安裝在全地形車(ATV)上的攝像頭以 5 公里/小時(shí)的速度進(jìn)行移動高光譜成像,。通過推掃式掃描,從ATV的運(yùn)動中獲得整個葡萄樹冠層的圖像,,并用于估計(jì)葡萄成分,。

On-the-go hyperspectral imaging with a camera mounted on an all-terrain vehicle (ATV) at 5 km/h. Images of the entire vine canopy were obtained from the ATV's motion, by push-broom scanning, and used for the estimation of grape composition.

數(shù)據(jù)處理上采用了支持向量機(jī)(SVM)算法,通過五折交叉驗(yàn)證,,對糖度的預(yù)測達(dá)到R2=0.91(RMSE=1.358°Brix),,對外部樣本的預(yù)測R2=0.92(RMSE=1.274°Brix)。對花青素濃度的預(yù)測也取得了R2=0.72(交叉驗(yàn)證)和R2=0.83(外部預(yù)測)的良好結(jié)果,。實(shí)現(xiàn)了對葡萄的可溶性固形物和花青素濃度的實(shí)時(shí)監(jiān)測,。

計(jì)算性能方面,在Intel Core i7處理器(16GB內(nèi)存)上,,處理36幅高光譜圖像平均需要5小時(shí)35分鐘,,相當(dāng)于每列掃描線處理時(shí)間約0.79秒。而使用訓(xùn)練好的SVM模型預(yù)測單個樣本僅需0.05秒,,展現(xiàn)了良好的實(shí)用性能,。

For data processing, the team employed support vector machine (SVM) algorithms. Through five-fold cross-validation, sugar content predictions reached R2=0.91 (RMSE=1.358°Brix), with external validation achieving R2=0.92 (RMSE=1.274°Brix). Anthocyanin concentration predictions also showed strong results: R2=0.72 (cross-validation) and R2=0.83 (external validation), enabling real-time monitoring of soluble solids and anthocyanins.

In terms of computational performance, processing 36 hyperspectral images on an Intel Core i7 processor (16GB RAM) averaged 5 hours and 35 minutes (~0.79 seconds per scan line). Trained SVM models required only 0.05 seconds per sample prediction, demonstrating practical usability.

圖3 / Figure 3:

(a)基于RGB通道的高光譜圖像(為便于說明,對直方圖進(jìn)行了歸一化),。 (b)像素光譜與葡萄標(biāo)準(zhǔn)光譜的R2值相關(guān)矩陣(應(yīng)用σ=1.0高斯平滑核函數(shù)),。 (c)基于R2≥0.75閾值的葡萄像素分割結(jié)果圖。

(a) Hyperspectral image from a block in red, green and blue (RGB) channels (histogram normalised for the sake of illustration). (b) Correlation matrix with R2 values between the pixel spectrum and a grape reference spectrum. A Gaussian smoothing was applied with σ?=?1.0. (c) Image with segmented grape pixels (pixels in (b) whose R2?≥?0.75). All the images were stretched in the horizontal axis for aesthetic purposes.

圖 4/ Figure 4:

可溶性固體物模型的交叉驗(yàn)證和預(yù)測結(jié)果.

Regression plot for (a) fivefold cross validation (R2?=?0.91; RMSE?=?1.358) and (b) prediction results (R2?=?0.92; RMSE?=?1.274) for the TSS models.

圖5 / Figure 5:

漿果花青素濃度的交叉驗(yàn)證和預(yù)測模型的回歸圖.

Regression plot for (a) fivefold cross validation (R2?=?0.72; RMSE?=?0.282) and (b) prediction results (R2?=?0.83; RMSE?=?0.211) for the anthocyanin concentration models.

『挑戰(zhàn)與未來展望 / Challenges and Future Outlook 』

盡管仍需解決環(huán)境干擾,、數(shù)據(jù)處理速度等問題,,這兩項(xiàng)研究證實(shí)了高光譜技術(shù)在田間應(yīng)用的可行性。

我們期待與更多農(nóng)業(yè)機(jī)構(gòu)合作,,提供專業(yè)的高光譜硬件解決方案,。我們的設(shè)備能夠?yàn)榭蛻舻难邪l(fā)團(tuán)隊(duì)提供高質(zhì)量的原始數(shù)據(jù),兼容多種數(shù)據(jù)格式,。隨著技術(shù)優(yōu)化,,這項(xiàng)技術(shù)有望成為智慧葡萄園的標(biāo)準(zhǔn)配置,為葡萄和葡萄酒產(chǎn)業(yè)帶來精細(xì)化管理的新時(shí)代,。

While challenges like environmental interference and processing speed remain, these studies confirm hyperspectral technology's field applicability.

We look forward to collaborating with agricultural institutions to provide professional hyperspectral hardware solutions. Our equipment delivers high-quality raw data in multiple compatible formats for research teams. As the technology evolves, it is poised to become a standard tool for smart vineyards, ushering in a new era of precision management for grape and wine production.

案例來源 / Source:

1. Benelli, A., Cevoli, C., Ragni, L., & Fabbri, A. (2022). Reprint of: In-field and non-destructive monitoring of grapes maturity by hyperspectral imaging. Biosystems Engineering, 223(Part B), 200-208.

2. Gutiérrez, S., Tardaguila, J., Fernández-Novales, J., & Diago, M. P. (2018). On-the-go hyperspectral imaging for the in-field estimation of grape berry soluble solids and anthocyanin concentration. Australian Journal of Grape and Wine Research, 24(2), 127-133.

相關(guān)產(chǎn)品

免責(zé)聲明

- 凡本網(wǎng)注明“來源:化工儀器網(wǎng)”的所有作品,,均為浙江興旺寶明通網(wǎng)絡(luò)有限公司-化工儀器網(wǎng)合法擁有版權(quán)或有權(quán)使用的作品,未經(jīng)本網(wǎng)授權(quán)不得轉(zhuǎn)載,、摘編或利用其它方式使用上述作品,。已經(jīng)本網(wǎng)授權(quán)使用作品的,應(yīng)在授權(quán)范圍內(nèi)使用,,并注明“來源:化工儀器網(wǎng)”,。違反上述聲明者,本網(wǎng)將追究其相關(guān)法律責(zé)任。

- 本網(wǎng)轉(zhuǎn)載并注明自其他來源(非化工儀器網(wǎng))的作品,,目的在于傳遞更多信息,,并不代表本網(wǎng)贊同其觀點(diǎn)和對其真實(shí)性負(fù)責(zé),不承擔(dān)此類作品侵權(quán)行為的直接責(zé)任及連帶責(zé)任,。其他媒體,、網(wǎng)站或個人從本網(wǎng)轉(zhuǎn)載時(shí),必須保留本網(wǎng)注明的作品第一來源,,并自負(fù)版權(quán)等法律責(zé)任,。

- 如涉及作品內(nèi)容、版權(quán)等問題,,請?jiān)谧髌钒l(fā)表之日起一周內(nèi)與本網(wǎng)聯(lián)系,,否則視為放棄相關(guān)權(quán)利。

手機(jī)版

手機(jī)版 化工儀器網(wǎng)手機(jī)版

化工儀器網(wǎng)手機(jī)版

化工儀器網(wǎng)小程序

化工儀器網(wǎng)小程序

官方微信

官方微信 公眾號:chem17

公眾號:chem17

掃碼關(guān)注視頻號

掃碼關(guān)注視頻號

采購中心

采購中心