| 應(yīng)用領(lǐng)域 | 地礦 |

|---|

Meusburger集團(tuán)是沖壓,、塑膠模具以及工裝夾具制造業(yè)內(nèi)高品質(zhì)產(chǎn)品的制造商,。持續(xù)、穩(wěn)定的供貨能力讓Meusburger集團(tuán)成為業(yè)內(nèi)高效率且值得信賴(lài)的合作伙伴

|

| 參考價(jià) | 面議 |

更新時(shí)間:2021-01-16 18:01:22瀏覽次數(shù):197

聯(lián)系我們時(shí)請(qǐng)說(shuō)明是化工儀器網(wǎng)上看到的信息,謝謝!

H 4062/796/1496

H 4062/796/1496

Meusburger集團(tuán)是沖壓,、塑膠模具以及工裝夾具制造業(yè)內(nèi)高品質(zhì)產(chǎn)品的制造商,。持續(xù)、穩(wěn)定的供貨能力讓Meusburger集團(tuán)成為業(yè)內(nèi)高效率且值得信賴(lài)的合作伙伴,,隨著價(jià)值鏈的延伸,,我們協(xié)助客戶(hù)不斷地取得成功。與我們同行,,客戶(hù)能夠以短的交貨周期和持續(xù)穩(wěn)定的高質(zhì)量地進(jìn)行沖壓、塑膠模具以及工裝夾具的有效制造,。

TEL:188-24-24-30-80

作為Meusburger集團(tuán)的一部分,,Meusburger公司是高精度標(biāo)準(zhǔn)件領(lǐng)域的市場(chǎng)者。分布于世界各地的客戶(hù)得益于我們眾多的標(biāo)準(zhǔn)化優(yōu)勢(shì)以及我們?cè)阡撹F行業(yè)50多年的工作經(jīng)驗(yàn),。公司不僅為客戶(hù)提供多元化的標(biāo)準(zhǔn)件產(chǎn)品,,同時(shí)向客戶(hù)提供特定工廠設(shè)備用品,Meusburger已成為沖壓,、塑膠以及工裝夾具制造業(yè)內(nèi)<B值得信賴(lài)的合作伙伴

我們?nèi)娴臉?biāo)準(zhǔn)零件范圍為連接沖頭提供了多種可能性–大量具有直接CAD數(shù)據(jù)輸出的零件,,并且有現(xiàn)貨供應(yīng),可用于快速設(shè)計(jì)和生產(chǎn),。

根據(jù)應(yīng)用和條件,,切割沖頭可以不同方式安裝或連接到模具中。本文仔細(xì)研究了各種類(lèi)型的沖頭附件,,包括滾珠鎖系統(tǒng),。

通過(guò)頭部幾何形狀固定

使用這種類(lèi)型的附件,切割沖頭通過(guò)刀頭夾在耐磨板和沖頭固定板之間,。的形狀是圓錐形,,圓柱形和瓶頸形。形狀的選擇取決于沖壓力和收縮力,,預(yù)期的使用壽命和可用空間,。見(jiàn)的類(lèi)型是根據(jù)DIN 9861的帶有圓錐形頭部的沖頭,它具有占用空間小的優(yōu)點(diǎn),。根據(jù)ISO 8020的帶有圓柱頭的沖頭需要更多的空間,,但是安裝更容易并且承受更大的縮回力。也可以選擇從Meusburger獲得該沖頭,,該沖頭可以立即使用,,其頭部高度準(zhǔn)確(E 55405),從而省去了在頭部上打磨的工作,。

根據(jù)DIN 5118的帶有瓶頸的沖頭或帶有30°錐形頭的沖頭適用于非常高的回縮力,。即使帶有瓶頸的沖頭需要較小的空間,,也需要使用HSS沉頭工具(WZB 318128)或安裝套筒(E 55301)引入的復(fù)雜的固定器。根據(jù)DIN 9844的帶有圓柱頭的沖頭具有4 mm的刀頭高度,,與刀頭直徑無(wú)關(guān),,這可以簡(jiǎn)化安裝。所有的變體都可以作為Meusburger的標(biāo)準(zhǔn)零件輕松獲得,。

The cutting punch is screwed to the head plate via a flange or a fixing hole on the front end.

For wire EDM contour punches, this fixing option allows for relatively simple production of the punch. In addition, thanks to the small space requirement, it is possible to place the cutting punches close together. It is also easy to underlay the cutting punches for height compensation after regrinding.

This attachment option is particularly suitable for filigree punches. Thanks to the standardised punch suspension piece, introduction of fixing threads in the punch is no longer necessary, and instead a radius contour is cut in. The bearing is floating in order to avoid unwanted forces on the punch. It is also easy to underlay the cutting punches here too. However, it must be ensured that both the punch and the retainer clip are underlaid so that the bearing of the punch is guaranteed to be floating.

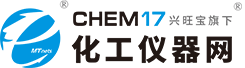

E 5665

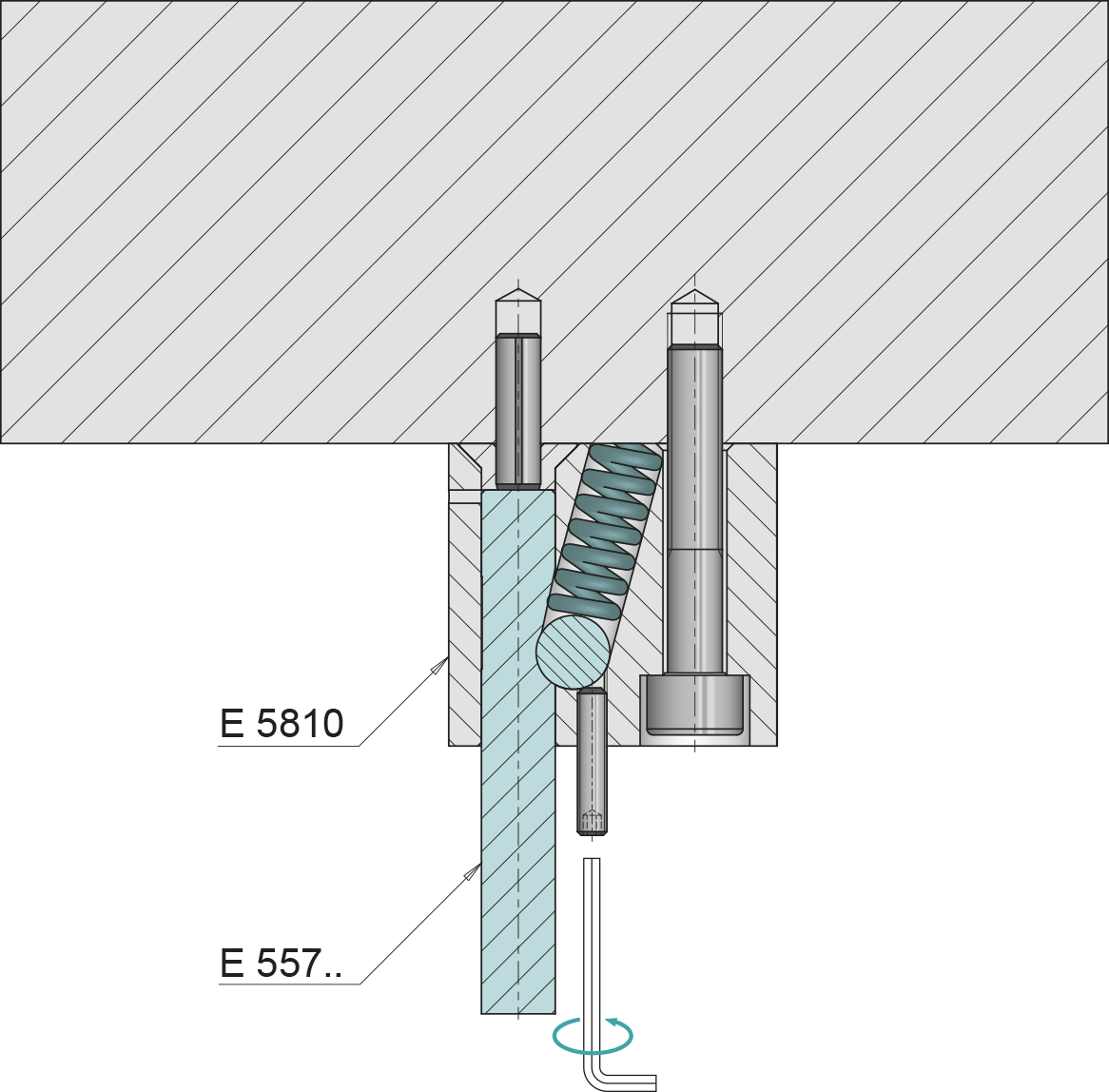

The characteristic feature of the quick-change systems or the ball-lock systems is a ball seat in the shaft of the punch. This is clamped in the punch retainer plate by a spring-loaded ball. To change the cutting punch, the ball is pushed back with a set screw and the punch can be quickly and easily removed. The set screw is then turned back to the starting position and the next punch is inserted. This eliminates the need to remove the entire retainer plate.

更多信息: To the products

Quick-change systems are mainly used in the production area of the automotive industry. Due to the compact, triangular design, the space inside the stamping die can be optimally utilised. However, this type of punch attachment is not suitable for high stroke rates and high retracting forces. Alternatively, cutting punches according to ISO 8020 with the appropriate punch retainer plates are used here.